|

Fabric scanners have taken the textile industry by storm, offering a level of precision and accuracy that was previously unimaginable. But have you ever wondered how these devices work their magic? The science behind fabric scanners is fascinating, involving a combination of advanced algorithms, computer vision, and material science. At its core, a fabric scanner is a sophisticated camera system that captures high-resolution images of fabrics. These images are then processed using machine learning algorithms, which extract relevant data about the fabric’s physical properties. The scanner can detect even the slightest variations in texture, color, and weave pattern, providing a detailed fingerprint of the material. This information is then used to create a digital twin of the fabric, allowing designers and manufacturers to analyze its behavior, predict performance, and identify potential defects. One of the key challenges in fabric analysis is accounting for the complexities of natural fibers. Cotton, wool, and silk, for instance, have unique properties that affect their behavior under different conditions. Fabric scanners use advanced material science to understand these properties, taking into account factors like moisture absorption, thermal conductivity, and tensile strength. This enables manufacturers to create products that are tailored to specific applications, from high-performance athletic wear to luxurious upholstery. The technology has far-reaching implications for textile research, enabling scientists to study the properties of fabrics at a molecular level. By analyzing the microstructure of materials, researchers can develop new fibers with improved strength, durability, and sustainability. Fabric scanners can also be used to analyze the impact of environmental factors on fabric degradation, helping to develop more resilient materials that withstand the test of time. In the world of fashion, fabric scanners are being used to develop smart textiles, which can adapt to environmental conditions, monitor vital signs, or even provide UV protection. Imagine wearing a dress that adjusts its color to match your mood or a shirt that regulates body temperature. Fabric scanners are making this vision a reality, enabling the creation of high-tech fabrics that interact with their surroundings. Moreover, fabric scanners are enabling the development of personalized fashion, where garments are tailored to individual preferences and body types. By analyzing fabric behavior, designers can create bespoke products that fit perfectly, reducing the need for alterations and returns. This shift towards personalized fashion has the potential to transform the industry, making it more agile, responsive, and environmentally friendly. In the world of aerospace, fabric scanners are being used to develop advanced materials that meet the extreme conditions of space exploration. By analyzing the properties of fabrics, researchers can create materials that withstand extreme temperatures, radiation, and other environmental factors. This has significant implications for space travel, enabling the creation of more durable and sustainable spacecraft. [fabric scanner]() In the automotive industry, fabric scanners are being used to develop smart textiles, which can monitor vital signs, detect accidents, or even provide UV protection. This technology has the potential to transform the industry, making vehicles safer, more comfortable, and more sustainable. In healthcare, fabric scanners are being used to develop advanced wound dressings, implantable devices, and medical textiles. By analyzing the properties of biomaterials, researchers can create products that promote healing, reduce infection rates, and enhance patient outcomes. The technology is also being used to develop personalized prosthetics, where fabric scanners analyze the properties of skin and muscle tissue to create bespoke devices. As the technology advances, we can expect to see fabric scanners integrated into various industries, from sports equipment to architecture. The possibilities are endless, and the diverse applications of fabric scanners are a testament to their potential to transform industries and improve lives. The rise of fabric scanners has also led to new collaborations between industries, where companies are working together to develop innovative solutions. This cross-pollination of ideas has the potential to drive innovation, as experts from different fields share their knowledge and expertise. In conclusion, fabric scanners represent a significant breakthrough in material science, offering a powerful tool for understanding the intricacies of fabrics. By unlocking the secrets of fabrics, we can create products that are stronger, more sustainable, and more adaptable to our needs. The technology is also driving innovation in textile manufacturing, where companies are developing new production methods that leverage the power of fabric scanners. This has led to the creation of more efficient and sustainable supply chains, where materials are sourced, produced, and distributed with minimal waste. Furthermore, fabric scanners are being used in historical preservation, where museums and cultural institutions can analyze and preserve fragile textiles. By capturing detailed information about fabric properties, conservators can develop targeted preservation strategies, ensuring that these cultural artifacts are protected for future generations. In the world of research, fabric scanners are enabling scientists to study the properties of fabrics at a molecular level. By analyzing the microstructure of materials, researchers can develop new fibers with improved strength, durability, and sustainability. Fabric scanners can also be used to analyze the impact of environmental factors on fabric degradation, helping to develop more resilient materials that withstand the test of time. As the technology continues to evolve, we can expect to see even more innovative applications, from self-healing fabrics to textiles that respond to environmental changes. The possibilities are endless, and the science behind fabric scanners is paving the way for a new era of innovation. |

Monthly Archives: December 2024

The Future of Fashion: Exploring the Role of a 3D Clothing Designer

| The fashion industry is undergoing a transformative phase, embracing technology to revolutionize traditional methods. At the heart of this transformation is the role of the *3D clothing designer*, a profession that blends creativity with cutting-edge technology. With the advent of 3D design, the future of fashion looks more innovative, sustainable, and accessible than ever before. This article delves into the fascinating world of 3D clothing design and its impact on the industry.

### The Rise of 3D Clothing Design In recent times, the fashion industry has witnessed a significant shift towards digitization. A major component of this shift is the adoption of 3D design techniques, which have redefined how clothing is conceptualized and produced. **3D clothing designers utilize advanced software** to create realistic virtual representations of garments. These designs can then be manipulated and adjusted in real-time, allowing designers to experiment with different textures, colors, and styles without the need for physical prototypes. This technology not only speeds up the design process but also reduces costs and wastage—a critical consideration in today’s environmentally conscious market. By minimizing the need for physical samples, *designers contribute to a more sustainable fashion industry*. ### Key Technologies in 3D Clothing Design Several technologies are integral to the work of a 3D clothing designer. Software such as CLO 3D, Browzwear, and TUKA3D enable designers to create lifelike models of their garments. These platforms offer features like real-time physics simulation, allowing fabrics to drape naturally as they would in reality. Additionally, 3D body scanning technology can create accurate digital avatars, personalized to fit consumers’ measurements, which enhances the customization process. Moreover, the rise of virtual reality (VR) and augmented reality (AR) blurs the line between digital and physical fashion. These technologies provide immersive experiences for both designers and consumers, allowing them to visualize and interact with products in ways previously unimaginable. ### Case Study: A 3D Clothing Designer’s Impact Consider the case of a well-known fashion brand that decided to incorporate 3D design tools into its workflow. Initially facing challenges with lengthy prototype production and high material costs, the company transitioned to a fully digital design process. This shift led to a 30% reduction in product time-to-market and a 20% decrease in material waste. Consumers benefited too, enjoying personalized and perfectly fitted garments thanks to precise 3D body scans. ### The Future Prospects of 3D Clothing Design Looking forward, the field of 3D clothing design holds immense potential. As technology becomes more sophisticated and accessible, the role of a *3D clothing designer* is expected to expand significantly. We anticipate the emergence of entirely virtual fashion shows, where designers can showcase their collections in immersive digital environments, reaching global audiences without the need for traditional runway events. Furthermore, the rise of sustainable fashion aligns perfectly with 3D design capabilities. By reducing waste and enabling quicker iterations, this technology is well-positioned to help the industry meet its environmental goals. In conclusion, the role of a 3D clothing designer is pivotal in shaping the future of fashion. By harnessing the power of technology, designers are not only enhancing creativity but also paving the way for a more sustainable and inclusive industry. As we continue to innovate and explore the boundaries of what is possible, the impact of 3D clothing design on fashion will undeniably be profound and lasting. |

Revolutionizing Fashion with 3D Design: The Future of the Fashion Industry

| ****

In the ever-evolving world of fashion, innovation is key. As the industry strives to become more sustainable and personalized, **_3D fashion design_** is emerging as a groundbreaking tool that promises to revolutionize the way we design, produce, and interact with fashion. But what exactly does this entail, and how is it reshaping the future of fashion? **Understanding 3D Fashion Design** At its core, **3D fashion design** refers to the use of three-dimensional technology to create digital garments. This process involves using specialized software to design clothes that can be viewed and manipulated in a virtual environment. Rather than producing physical prototypes, designers can create detailed digital renderings that provide a realistic representation of what the finished product will look like. **Benefits of 3D Fashion Design** The advantages of integrating this innovative technology into fashion are numerous. One of the primary benefits is the potential for _drastic waste reduction_. With traditional fashion, numerous samples and iterations are required to perfect a design, leading to significant fabric wastage. However, by using 3D design, designers can perfect their creations digitally before producing a single physical item, thereby aligning with sustainability goals. Additionally, **3D design** allows for _greater customization and personalization_. Designers can easily alter colors, patterns, and sizes to meet individual preferences, offering a more bespoke fashion experience. Customers can visualize how garments will look and fit before committing to a purchase, enhancing their buying confidence and reducing returns. **Innovation in the Fashion Industry** A case in point is the collaboration between established brands and 3D technology companies. Companies like [LincTex]() are pioneering the adoption of **3D fashion design** by providing tools that enable designers to push the boundaries of creativity while maintaining precision in pattern-making and fit. Moreover, **3D fashion design** streamlines the product development cycle. By shortening the time from concept to market, brands can respond more swiftly to fashion trends, staying ahead of the curve and meeting consumer demands without the prolonged delays inherent in traditional production methods. **Impact on the Role of Fashion Designers** With the rise of **3D fashion design**, the role of the fashion designer is also evolving. Designers are now required to be tech-savvy, merging their traditional skills with an in-depth understanding of digital tools. This evolution is fostering a new breed of designers who can marry aesthetic vision with technical prowess. Fashion institutions are taking note by incorporating digital design coursework into their curriculums, ensuring that the next generation of designers is well-equipped to harness the full potential of **3D design technology**. **Conclusion** In conclusion, as the fashion industry faces increasing pressure to become more innovative, efficient, and sustainable, **3D fashion design** stands out as a powerful solution. The technology not only brings operational efficiencies and environmental benefits but also offers enhanced creative possibilities for designers. As more brands and designers embrace this digital revolution, it is clear that _3D fashion design_ will be a formidable force in shaping the future of fashion. For more insights into how technology is transforming fashion, explore [LincTex’s innovations](). |

CHLORINE TABLETS VS. CHLORINE POWDER: KEY DIFFERENCES YOU NEED TO KNOW

Chlorine Tablets vs. Chlorine Powder: Key Differences You Need to Know

Maintaining a clean and safe swimming pool is essential for any pool owner, whether it’s for a private backyard or a commercial facility. One of the primary tools used to keep the pool water sanitized is chlorine. It is available in various forms, but the two most popular choices are Chlorine tablets and Chlorine powder. Both serve the same purpose of disinfecting the water, but they have different characteristics and uses. As a Chlorine tablets supplier and manufacturer, we believe it’s crucial to understand the differences between these two options so you can make the best choice for your pool maintenance needs.

In this article, we’ll explore the main differences between Chlorine tablets and Chlorine powder, including their use, convenience, cost-effectiveness, and where to buy the best Chlorine tablets. Understanding these points will help you choose the right option for your pool and maintenance schedule.

What Are Chlorine Tablets?

Chlorine tablets are solid forms of chlorine that dissolve slowly in water, releasing chlorine over an extended period. They are commonly made from trichloroisocyanuric acid (trichlor), which is a stabilized form of chlorine that resists degradation by sunlight. This makes Chlorine tablets an ideal choice for outdoor pools, where sun exposure can break down chlorine quickly.

Chlorine tablets come in different sizes, typically 1-inch and 3-inch tablets, with the larger tablets dissolving more slowly. They are convenient to use as they can be placed in a floating dispenser, skimmer basket, or chlorinator, ensuring a continuous release of chlorine into the pool. This allows for easier pool maintenance as the chlorine levels remain consistent without frequent manual application.

What Is Chlorine Powder?

Chlorine powder, also known as calcium hypochlorite or granular chlorine, is a highly concentrated form of chlorine. Unlike Chlorine tablets, Chlorine powder dissolves rapidly when added to the pool, which makes it a quick solution for boosting chlorine levels. It is commonly used for pool shocking, where a large dose of chlorine is needed to eliminate contaminants like bacteria, algae, and other impurities.

Chlorine powder does not contain stabilizers like cyanuric acid, meaning that it can break down quickly in the presence of sunlight. This makes it less effective for long-term pool maintenance but perfect for short-term chlorination or when an immediate increase in chlorine levels is needed.

Key Differences Between Chlorine Tablets and Chlorine Powder

Now that we’ve covered the basics of both forms of chlorine, let’s take a deeper look at the main differences between Chlorine tablets and Chlorine powder.

Release Rate

The most significant difference between the two lies in the rate at which they release chlorine into the pool. Chlorine tablets dissolve slowly and provide a steady, consistent release of chlorine over time. This means that once you place the tablets in the pool’s chlorinator or dispenser, you don’t need to monitor or add chlorine frequently.

In contrast, Chlorine powder dissolves much faster and releases chlorine immediately upon application. This makes it an ideal option for quickly boosting chlorine levels or performing a pool shock. However, the rapid dissolution of Chlorine powder means it doesn’t provide the same long-term, steady chlorine release as Chlorine tablets.

Ease of Use

When it comes to ease of use, Chlorine tablets offer more convenience. Once you place them in the appropriate dispenser, they gradually dissolve and do the work for you. This makes them perfect for pool owners who want a low-maintenance option for keeping their pool water safe and clean.

On the other hand, Chlorine powder requires more active management. You need to manually measure and dissolve the powder before adding it to the pool. If not done correctly, there’s a risk of uneven chlorine distribution, which can lead to higher chlorine levels in certain areas of the pool. Therefore, Chlorine tablets are a better choice for those seeking a hassle-free and consistent approach to pool maintenance.

Cost-Effectiveness

Both Chlorine tablets and Chlorine powder come with their own set of costs, but overall, Chlorine tablets tend to be a more cost-effective solution for long-term pool maintenance. While Chlorine powder may seem cheaper upfront, it dissolves quickly and is often used in larger quantities. This means that over time, you’ll need to purchase more of it to maintain the right chlorine levels.

In contrast, Chlorine tablets last longer, which means fewer replacements and less frequent purchases. Additionally, when you buy wholesale Chlorine tablets, you can often get a better deal and reduce the cost per unit, making it even more affordable in the long run.

Stabilization

A crucial difference is the stabilization factor. Chlorine tablets are typically stabilized with cyanuric acid, which helps protect the chlorine from being broken down by UV rays from the sun. This is particularly important for outdoor pools, as the sun’s UV rays can cause chlorine to dissipate quickly. By using Chlorine tablets, you ensure that the chlorine remains active for a longer period, making them ideal for regular pool maintenance.

In contrast, Chlorine powder is typically unstabilized, meaning it’s more susceptible to degradation by sunlight. For pools exposed to direct sunlight, Chlorine tablets offer a more stable solution.

Application for Pool Shocking

While both Chlorine tablets and Chlorine powder sanitize pool water, they are used for different purposes. Chlorine powder is most commonly used for pool shocking, a process that involves adding a large amount of chlorine to the pool to kill bacteria, algae, and other contaminants quickly. If you need to restore your pool’s sanitation levels after heavy use or contamination, Chlorine powder is the go-to solution.

Chlorine tablets, on the other hand, are better suited for maintaining consistent chlorine levels over time, making them ideal for routine sanitization rather than emergency shocking.

Storage and Handling

Storing Chlorine tablets is relatively simple. They are solid and can be kept in a dry, cool place without special precautions. In contrast, Chlorine powder is more concentrated and needs to be stored with greater care. Improper storage of Chlorine powder can lead to the release of harmful fumes, so it’s essential to follow the manufacturer’s storage instructions carefully.

Which One Should You Choose?

Both Chlorine tablets and Chlorine powder have their merits. For those who are looking for a long-term, steady solution for maintaining pool water quality, Chlorine tablets are the better choice. They provide consistent chlorine levels, are easy to use, and require less frequent application.

However, if you need a quick solution to boost chlorine levels or perform a pool shock, Chlorine powder is the ideal option. It’s highly effective for quick sanitization but requires more attention during application.

Where to Buy Chlorine Tablets

If you’re looking to buy the best Chlorine tablets, it’s important to choose a reliable Chlorine tablets supplier. As a Chlorine tablets factory and supplier, we offer high-quality products at competitive prices. You can also find wholesale Chlorine tablets for bulk purchases, making it more affordable to maintain your pool.

Conclusion

In conclusion, both Chlorine tablets and Chlorine powder are essential tools for pool maintenance, but they serve different purposes. Chlorine tablets are perfect for steady, long-term chlorination, while Chlorine powder is ideal for quick fixes and pool shocking. Understanding the differences between the two will help you make an informed decision based on your pool’s needs. Whether you choose Chlorine tablets or Chlorine powder, maintaining proper sanitation levels is key to keeping your pool safe, clean, and enjoyable for everyone.

UNDERSTANDING THE ROLE OF CHLORINE TABLETS: WHY THEY ARE THE KEY TO POOL CLEANING

Click:china electric assist cargo tricycle suppliers

Understanding the Role of Chlorine Tablets: Why They Are the Key to Pool Cleaning

Maintaining a clean and safe swimming pool is crucial for both residential and commercial pool owners. Whether you have a small backyard pool or manage a large public swimming area, keeping the water clear of harmful bacteria, algae, and debris is essential for safety and enjoyment. One of the most effective ways to maintain clean pool water is through the use of chlorine tablets. In this article, we will explore the important role of chlorine tablets, why they are vital for pool sanitation, and how to choose the right product for your needs.

I.The Importance of Chlorine in Pool Water

Chlorine is one of the most powerful disinfectants available for pool water. When chlorine is introduced into pool water, it reacts with bacteria, algae, and other microorganisms, killing them and preventing further contamination. Chlorine tablets are an efficient and convenient way to release chlorine into the pool, ensuring that the water remains safe and free of harmful pathogens.

While chlorine can be added to pool water in various forms, such as liquid or granular chlorine, chlorine tablets have become the go-to solution for many pool owners. They offer a slow-dissolving option, ensuring a consistent release of chlorine over an extended period. This steady release helps to maintain the appropriate chlorine levels in the pool, reducing the need for frequent additions and manual monitoring.

II.How Chlorine Tablets Work

Chlorine tablets are typically made of a combination of calcium hypochlorite or trichloroisocyanuric acid, both of which are powerful forms of chlorine. When these tablets dissolve in water, they gradually release chlorine, which is then able to sanitize the water by killing bacteria, algae, and viruses. The slow-dissolving nature of chlorine tablets means that they provide a consistent supply of chlorine over time, preventing fluctuations in pool water quality.

One of the main benefits of using chlorine tablets is the ability to control the chlorine level in the pool without frequent reapplication. These tablets are designed to dissolve at a steady pace, ensuring that the chlorine remains active and effective throughout the day. This slow release of chlorine also helps maintain the proper pH levels in the pool, which is vital for keeping the water balanced and preventing irritation to swimmers.

III.Why Chlorine Tablets Are the Key to Pool Cleaning

There are several reasons why chlorine tablets are an essential part of maintaining a clean and safe swimming pool:

Effective Sanitization:

Chlorine tablets provide the most reliable and consistent form of sanitization for your pool. By continually releasing chlorine, they ensure that the pool remains free of harmful bacteria and pathogens, helping to protect swimmers from illness.

Convenience:

Using chlorine tablets is incredibly easy and convenient. Simply place the tablets in a floating dispenser, skimmer basket, or chlorinator, and the tablets will dissolve gradually, releasing chlorine into the pool over time. This eliminates the need for constant manual application and allows you to focus on enjoying your pool rather than worrying about water treatment.

Cost-Effective:

Compared to other forms of chlorine, chlorine tablets are often more cost-effective in the long run. Although the initial cost may be slightly higher, their slow-dissolving nature means you’ll need fewer tablets over time. This helps save money on pool maintenance while ensuring the pool water stays clean and safe.

Stabilized Chlorine:

Most chlorine tablets are stabilized with cyanuric acid, which helps protect the chlorine from being broken down by sunlight. In outdoor pools, where UV rays can cause chlorine to dissipate quickly, stabilized chlorine tablets are especially effective. By choosing stabilized tablets, you can reduce the frequency of chlorine application, helping to maintain optimal sanitation levels.

IV.How to Choose the Best Chlorine Tablets for Your Pool

When selecting chlorine tablets for your pool, there are a few important factors to consider:

Chlorine Concentration:

Chlorine tablets come in various concentrations, typically ranging from 90% to 99%. The higher the concentration, the more effective the tablet will be at sanitizing the pool. If you have a large pool or one that experiences a lot of sunlight, you may want to opt for tablets with a higher concentration to ensure long-lasting results.

Stabilized vs. Unstabilized Chlorine Tablets:

As mentioned earlier, stabilized chlorine tablets contain cyanuric acid, which helps protect the chlorine from UV degradation. These are ideal for outdoor pools or pools that are exposed to direct sunlight. Unstabilized chlorine tablets, on the other hand, are better suited for indoor pools or pools that are not exposed to sunlight as frequently.

Tablet Size:

Chlorine tablets typically come in 1-inch or 3-inch sizes. Larger pools will require more tablets or larger tablets to maintain proper chlorine levels. It’s important to follow the manufacturer’s guidelines to determine the correct dosage and ensure that you’re not overusing the chlorine.

Where to Buy Chlorine Tablets:

When you decide to buy chlorine tablets, it’s important to find a reliable and trustworthy supplier. Look for the best chlorine tablets supplier who offers high-quality products at competitive prices. A reputable supplier will provide you with the right tablets for your pool size and type, ensuring that you get the best results for your investment.

V.Buying Cheap Chlorine Tablets

While quality should always be a top priority when purchasing chlorine tablets, it’s also important to find affordable options. Buying cheap chlorine tablets doesn’t mean compromising on quality. Many online retailers and local pool supply stores offer discounts and promotions, allowing you to buy chlorine tablets at a more affordable price. Keep in mind that purchasing in bulk can also save you money in the long run, as you’ll have a sufficient supply of tablets for multiple pool cleaning cycles.

Before buying chlorine tablets, always check the product reviews and ensure that the supplier has a solid reputation for providing effective and reliable pool chemicals. Opt for products that are designed for your pool’s specific needs, and never sacrifice quality for price.

VI.Conclusion

Chlorine tablets are an indispensable part of maintaining clean, safe, and clear pool water. They offer a convenient and cost-effective way to sanitize your pool, providing a steady release of chlorine that ensures consistent water quality. By selecting the best chlorine tablets for your pool and buying from a reliable supplier, you can enjoy a well-maintained swimming pool that’s safe for all swimmers. Whether you are looking to buy chlorine tablets for a small backyard pool or a large commercial swimming area, understanding their role and selecting the right product is key to achieving the best results.

FACTORS AFFECTING THE SERVICE LIFE OF GEOTEXTILES: DURABILITY AND MAINTENANCE

Click:Hair growth treatment

Factors Affecting the Service Life of Geotextiles: Durability and Maintenance

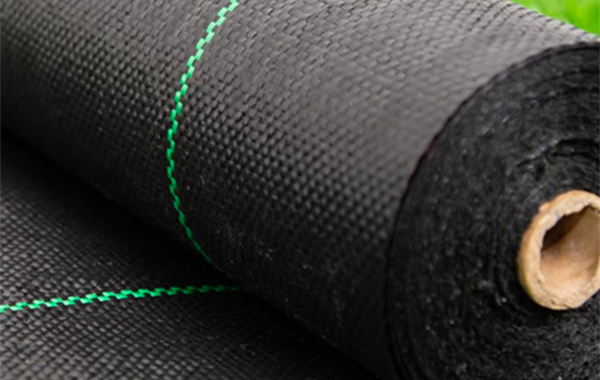

Geotextiles are widely used in civil engineering and construction projects for their ability to enhance soil stability, improve drainage, and provide erosion control. They play a crucial role in applications such as road construction, foundation stabilization, and landscaping. However, the service life of geotextiles is influenced by several factors, including material composition, environmental conditions, and maintenance practices. Understanding these factors is essential for maximizing the longevity and performance of geotextiles in various applications.

1. Material Composition and Quality

The durability of geotextiles begins with the material they are made from. Geotextiles are typically produced from synthetic materials such as polypropylene, polyester, or polyethylene. Each of these materials has different properties, such as resistance to UV radiation, chemicals, and temperature fluctuations, which directly affect their lifespan.

Polypropylene is commonly used for its resistance to chemical degradation and ability to perform well in high-strength applications.

Polyester geotextiles are favored for their strength and resistance to UV radiation, making them suitable for applications exposed to sunlight.

Polyethylene, while less common, is highly resistant to abrasion and is often used for applications involving extreme conditions.

When purchasing geotextiles, it’s important to consider the specific requirements of the project and choose materials that will withstand the environmental conditions to which they will be exposed. For those looking for affordable solutions, it’s possible to buy geotextile from reputable sources that offer good quality products at competitive prices.

2. Exposure to Environmental Conditions

Environmental factors play a significant role in the degradation of geotextiles. The primary factors that affect the service life of geotextiles include:

UV Radiation:

Prolonged exposure to ultraviolet (UV) rays can break down the chemical structure of geotextiles, particularly those made from polypropylene and polyethylene. UV degradation can lead to the weakening of fibers and eventual failure of the geotextile. To mitigate this, manufacturers often add UV stabilizers to their products, but over time, these additives may lose effectiveness.

Temperature Fluctuations:

Geotextiles that experience extreme temperature changes, such as those in hot climates or areas with harsh winters, are more likely to suffer from physical wear and tear. High temperatures can cause the materials to become brittle, while freezing temperatures can make them more prone to cracking.

Chemical Exposure:

Geotextiles used in soil stabilization or drainage systems may come into contact with various chemicals, such as fertilizers, pesticides, or industrial effluents. The composition of the geotextile determines its resistance to chemical degradation. Polyester-based geotextiles are generally more resistant to chemicals than polypropylene ones, making them a better choice for chemically aggressive environments.

Mechanical Stress:

Geotextiles are subject to mechanical stress, especially in road construction and other high-load applications. Over time, repeated loading and unloading can cause the fibers in the geotextile to break down. Proper installation and maintenance can help alleviate some of the stress on the material, but eventually, wear and tear will take its toll.

In regions with extreme conditions, it’s important to select a geotextile that has been specifically designed to withstand the local environment. For instance, if you’re working in a location with high UV radiation, it might be best to purchase geotextiles that are treated with UV inhibitors to increase their lifespan.

3. Proper Installation Practices

The service life of geotextiles is also highly dependent on proper installation techniques. Incorrect installation can result in premature failure of the geotextile, regardless of the quality of the material. Common installation issues include:

Overstretching:

When geotextiles are overstretched during installation, they may lose their strength and fail prematurely. It’s essential to install the material without over-tensioning it to ensure optimal performance.

Improper Overlap:

Geotextiles are often used in layered systems, where sections of the material are overlapped to ensure continuous coverage. If the overlap is insufficient or improperly aligned, the geotextile may fail under load.

Poor Anchoring:

Geotextiles must be properly anchored to prevent movement or displacement over time. Improper anchoring can result in the material shifting out of place, causing it to lose its effectiveness in providing stability or filtration.

Hiring a professional with expertise in geotextile installation can help prevent these issues and ensure that the material performs as expected over its service life.

4. Regular Maintenance and Inspections

Regular maintenance and inspections are vital for extending the lifespan of geotextiles, especially in projects where the material is exposed to harsh conditions. Some key maintenance practices include:

Cleaning:

Geotextiles used in drainage applications can become clogged with debris, silt, or sediment. This can reduce their filtration efficiency and lead to the failure of the entire system. Regular cleaning of geotextiles, especially those used in erosion control or drainage systems, is essential to maintain performance.

Repairs:

If geotextiles become damaged due to mechanical stress, punctures, or environmental factors, they should be promptly repaired or replaced. Small holes or tears in the material can compromise its integrity and lead to larger issues down the line.

Monitoring:

Regular monitoring of geotextiles in use can help detect signs of wear early, allowing for timely intervention before the material fails completely. Signs to watch for include visible degradation, stretching, or shifting of the material.

For those looking to replace worn-out geotextiles or add more to their existing systems, finding a cheap geotextile manufacturer who offers reliable and durable products can make a significant difference in reducing overall project costs.

5. Conclusion

The service life of geotextiles is influenced by various factors, including material composition, exposure to environmental conditions, installation practices, and ongoing maintenance. By understanding these factors and selecting the right geotextile for your specific needs, you can ensure that the material performs effectively for as long as possible.

To get started on your next project, consider sourcing high-quality materials from trusted suppliers. If you’re looking for an affordable option, you can buy geotextile from reputable manufacturers who offer a balance of cost and quality. For bulk orders or long-term projects, it’s also worth reaching out to a cheap geotextile manufacturer who can provide cost-effective solutions without compromising on material performance. By taking these steps, you’ll be well on your way to ensuring the durability and longevity of your geotextile installations.

FJ Bearing news report from local TV:Adhering to Innovating, Continuous Transforming and Upgrading, Substituting the single bearing into Unit Bearing, the Maintenance-free Auto Hub Bearing Unit has Been Newly Developed by FJ Bearing

Click:duraclik connector

Let’s focus on the development experiences of the Fujian YongAn Bearing Co., Ltd, which are specialized in bearing technology research and development, and expanding the huge market from small parts. Please watch the report delivered from the scene. What we are seeing now is the maintenance-free bearing unit newly developed by FJ Bearing, and also is Regional Development Project of Fujian Science and Technology Department in this year. Compared with the old traditional single row bearing, this type possessed many performances such as lighted-weight, integrated, long life and free maintenance, etc. At present, the trail manufacture of this product has completed, and has a vast market prospect. With the characteristic of high technology and complicated manufacturing process, the commercial maintenance-free hub bearing unit is one of priority development high end bearings in the industry. As the commercial vehicle development progresses, the occupation ratio of the commercial maintenance-free hub bearing unit in the commercial vehicle hub market is increasing year by year. By means of focusing on the market change, and aiming at the commanding height in this industry, FJ Bearing developed, tackled the key problems and made a breakthrough on commercial maintenance-free hub bearing unit. This type of bearing is listed in the project which is established by Fujian Provincial Science and Technology Department announced in 2021. Since now, research and development project for this unit has been put into trial production, meanwhile, and matching corresponding advanced heat treatment instrument, high precision automatic grinding production line and assembly line have been put into use. Zhong Yuan, the Deputy General Manager of FJ Bearing: “During the development process of maintenance-free hub bearing unit, we have tightly integrated the high precision bearing design technology, the assurance of machining precision, precision machining of grease and sealing flange, inspection of oil gap together, therefore, realized the goals which are meeting the design goal we proposed and the user requirement.” Since the FJ Bearing has been established, they are adhering to innovating, continuous transforming and upgrading under the supports from all levels of technology department, the products are keep updating and continuously renewing, the products has transformed from agricultural machinery products, engineering machinery products into the auto mobile products, the enterprise are about to exploring the high end market. Zhong Yuan, the Deputy General Manager of FJ Bearing: “Since now, we have developed over 1000 types of bearings, which are widely used in host matching on automobile mechanical machinery at domestic and abroad. We will focus on developing the commercial maintenance-free bearing unit in the next step, and we will substitute the unitized bearing product for single bearing product, and we will realize the product developed into high precision and high value.”

Contact Info:

Export dept.86- 86-0598-3634197

Email: [email protected]

Website:www.yazc.com.cn

Zip Code: 366000

Address: No.699,PuLing Road,YongAn city,FuJian Province,China