# Ambient Pressure Definition and Its Importance in Various Fields

## What is Ambient Pressure?

Ambient pressure refers to the pressure of the surrounding environment at any given location. It’s the force exerted by the atmosphere or any other surrounding medium on objects within it. This pressure is typically measured in units such as pascals (Pa), atmospheres (atm), or pounds per square inch (psi).

The standard atmospheric pressure at sea level is approximately 101,325 pascals (101.325 kPa) or 1 atmosphere (atm). However, ambient pressure can vary significantly depending on factors like altitude, weather conditions, and whether the environment is enclosed or open.

## How Ambient Pressure is Measured

Several instruments are used to measure ambient pressure:

– Barometers: Measure atmospheric pressure

– Pressure gauges: Measure pressure in enclosed systems

– Manometers: Measure pressure differences

Digital pressure sensors have become increasingly common in modern applications, providing precise and real-time measurements of ambient pressure.

## Importance of Ambient Pressure in Different Fields

### 1. Aviation and Aerospace

In aviation, ambient pressure plays a critical role in:

– Aircraft performance calculations

– Altitude determination

– Cabin pressurization systems

– Spacecraft design for vacuum conditions

Pilots rely on accurate ambient pressure readings to determine their true altitude and ensure safe flight operations.

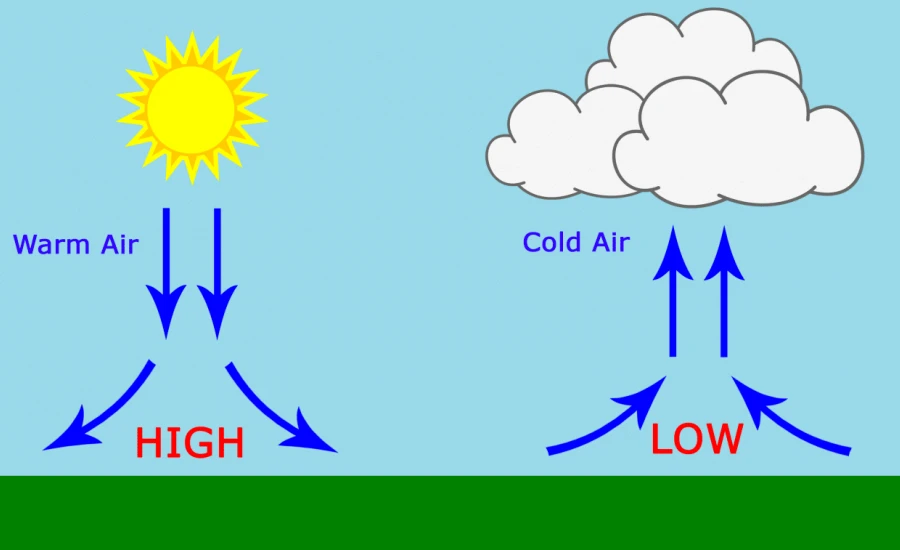

### 2. Meteorology and Weather Forecasting

Meteorologists use ambient pressure measurements to:

– Predict weather patterns

– Identify high and low-pressure systems

– Forecast storms and other severe weather events

– Study climate change patterns

Changes in atmospheric pressure often precede significant weather changes, making these measurements invaluable for forecasting.

### 3. Industrial Applications

Many industrial processes depend on precise ambient pressure control:

– Chemical manufacturing

– Food processing and packaging

– Semiconductor production

– Pharmaceutical manufacturing

Maintaining specific pressure conditions is often essential for product quality and process efficiency.

### 4. Medical and Healthcare

Ambient pressure affects various medical applications:

– Hyperbaric oxygen therapy

– Altitude sickness treatment

– Respiratory therapy equipment

– Surgical procedures in controlled environments

Understanding pressure effects on the human body is crucial for both treatment and prevention of pressure-related health issues.

### 5. Deep Sea Exploration

Underwater environments present extreme pressure conditions:

– Submersible vehicle design

– Diving equipment development

– Marine biology research

– Underwater construction

The tremendous pressure increases with depth create unique challenges for equipment and personnel working in these environments.

## Factors Affecting Ambient Pressure

Several factors influence ambient pressure measurements:

– Altitude: Pressure decreases with increasing elevation

– Temperature: Warmer air is less dense, affecting pressure

– Weather systems: High and low-pressure areas move across the Earth’s surface

– Humidity: Water vapor content can slightly affect air pressure

– Geographic location: Pressure varies with latitude and local topography

## Practical Applications in Daily Life

Ambient pressure affects many everyday items and activities:

– Tire pressure monitoring in vehicles

– Weather station home devices

– Altitude adjustments for cooking recipes

– Sports equipment performance (e.g., balls used at different altitudes)

– Beverage carbonation and packaging

## Conclusion

Understanding ambient pressure is fundamental across numerous scientific, industrial, and everyday applications. From ensuring safe air travel to predicting weather patterns and enabling deep-sea exploration, the measurement and control of ambient pressure continue to play a vital role in advancing technology and improving our quality of life. As we develop new technologies and explore more extreme environments, our understanding and utilization of ambient pressure principles will only become more important.