# ELECTRONICON E62.S23-563M30 Capacitor Technical Specifications and Applications

The ELECTRONICON E62.S23-563M30 capacitor is a high-performance component designed for demanding industrial and commercial applications. Known for its reliability and efficiency, this capacitor is widely used in power electronics, renewable energy systems, and other advanced technologies. Below, we delve into its technical specifications and explore its key applications.

## Technical Specifications

The ELECTRONICON E62.S23-563M30 capacitor boasts a range of impressive features that make it suitable for high-stress environments:

– Capacitance: 56 µF

– Voltage Rating: 300 V AC

– Tolerance: ±5%

– Temperature Range: -40°C to +85°C

– Case Size: Compact and robust design

– Dielectric Material: High-quality polypropylene film

– Mounting Type: Screw terminals for secure installation

– Safety Standards: Compliant with IEC 61071 and EN 60252-1

These specifications ensure that the capacitor delivers consistent performance even under challenging conditions, making it a reliable choice for critical applications.

## Key Applications

The ELECTRONICON E62.S23-563M30 capacitor is versatile and finds use in a variety of industries. Some of its primary applications include:

### 1. Power Electronics

In power electronics, this capacitor is used for filtering, energy storage, and power factor correction. Its high capacitance and voltage rating make it ideal for smoothing out voltage fluctuations and ensuring stable operation of electronic devices.

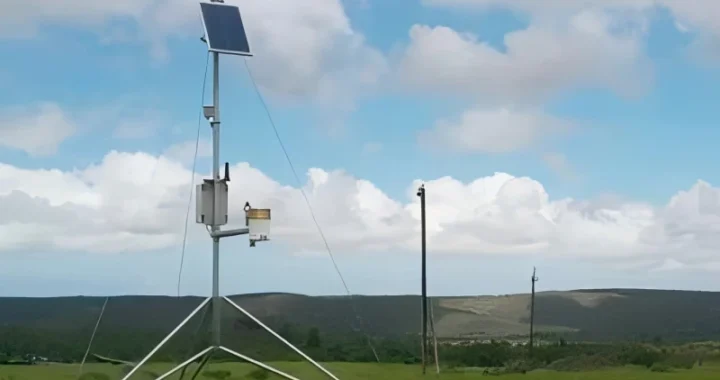

### 2. Renewable Energy Systems

Renewable energy systems, such as solar inverters and wind turbines, require capacitors that can handle high voltages and temperatures. The E62.S23-563M30 is well-suited for these applications, providing reliable performance in harsh environments.

### 3. Industrial Automation

In industrial automation, capacitors are used in motor drives, frequency converters, and other control systems. The E62.S23-563M30’s robust design and high tolerance make it a dependable component in these systems.

### 4. Medical Equipment

Medical devices often require capacitors with high reliability and precision. The E62.S23-563M30 meets these requirements, ensuring safe and efficient operation of critical medical equipment.

## Advantages of the ELECTRONICON E62.S23-563M30 Capacitor

The ELECTRONICON E62.S23-563M30 capacitor offers several advantages that set it apart from other capacitors in its class:

– High Reliability: Designed for long-term use with minimal maintenance.

– Energy Efficiency: Low losses and high efficiency contribute to energy savings.

– Compact Design: Its small size allows for easy integration into various systems.

– Compliance with Standards: Meets international safety and performance standards, ensuring quality and reliability.

## Conclusion

The ELECTRONICON E62.S23-563M30 capacitor is a high-quality component that excels in demanding applications. Its technical specifications, combined with its versatility and reliability, make it a preferred choice for industries ranging from power electronics to renewable energy and beyond. Whether you’re designing a new system or upgrading an existing one, the E62.S23-563M30 is a capacitor you can trust.