# Pottery Tools: Essential Equipment for Ceramic Artistry

Pottery is an ancient art form that has been practiced for thousands of years. Whether you’re a beginner or an experienced ceramic artist, having the right pottery tools is essential for creating beautiful and functional pieces. In this article, we’ll explore some of the most important tools used in pottery and how they can enhance your ceramic artistry.

## 1. Pottery Wheel

The pottery wheel is perhaps the most iconic tool in ceramic art. It allows artists to shape clay into symmetrical forms with precision and ease. Modern pottery wheels come in various sizes and types, including electric and kick wheels. The choice of wheel depends on your skill level and the type of work you plan to create.

## 2. Clay

Clay is the fundamental material in pottery. There are different types of clay, such as earthenware, stoneware, and porcelain, each with its own unique properties. The type of clay you choose will affect the texture, color, and durability of your finished piece. It’s important to select the right clay for your project to achieve the desired results.

## 3. Kiln

A kiln is an essential tool for firing pottery. It is a high-temperature oven that hardens the clay and sets the glaze. Kilns come in various sizes and can reach temperatures of up to 2,300 degrees Fahrenheit. Properly firing your pottery is crucial for ensuring its strength and longevity.

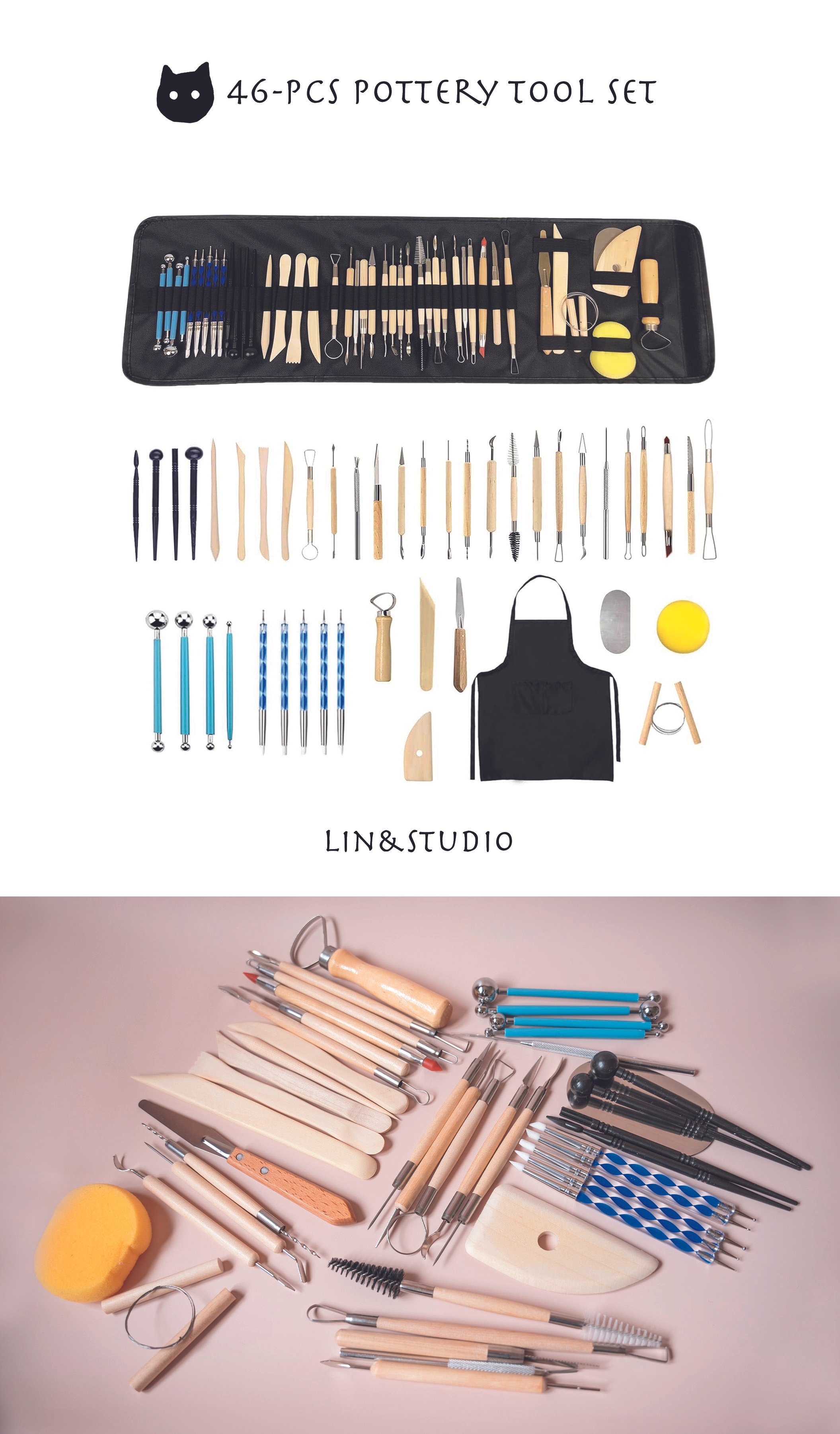

## 4. Pottery Tools Set

A basic pottery tools set typically includes a variety of instruments such as wire cutters, ribs, loop tools, and needle tools. These tools help in shaping, trimming, and detailing your pottery. Wire cutters are used to slice through clay, while ribs and loop tools help in smoothing and refining the surface. Needle tools are perfect for carving intricate designs and adding fine details.

## 5. Sponges

Sponges are indispensable in pottery for smoothing and cleaning the surface of your work. They come in different shapes and sizes, and some are specifically designed for pottery. Sponges help in absorbing excess water and removing any imperfections, giving your piece a polished finish.

## 6. Brushes

Brushes are used for applying glazes and underglazes to your pottery. They come in various sizes and bristle types, allowing for different application techniques. A good set of brushes can help you achieve a wide range of effects, from smooth, even coats to textured, artistic finishes.

## 7. Calipers

Calipers are precision tools used to measure the thickness and diameter of your pottery. They ensure that your pieces are uniform and meet specific size requirements. Calipers are especially useful when creating sets of matching items, such as cups or bowls.

## 8. Banding Wheel

A banding wheel is a rotating platform that allows you to easily turn your pottery while working on it. This tool is particularly useful for applying decorations, glazes, or underglazes evenly around the piece. It provides stability and control, making detailed work much easier.

## 9. Extruder

An extruder is a tool that pushes clay through a shaped die to create consistent forms, such as handles, coils, or decorative elements. It is a time-saving device that can help you achieve uniformity in your work, especially when creating multiple pieces with similar features.

## 10. Slab Roller

A slab roller is used to flatten clay into even slabs, which can then be cut and shaped into various forms. This tool is particularly useful for creating flat pieces like tiles, plates, or large panels. It ensures that your slabs are of consistent thickness, which is important for even drying and firing.

In conclusion, having the right pottery tools is crucial for any ceramic artist. Each tool serves a specific purpose and contributes to the overall quality and creativity of your work. Whether you’re just starting out or are a seasoned potter,

Keyword: Pottery tools